tear test of fabric|high tear strength testing : tv shopping Tearing strength is the resistance of the fabric against tearing or force required to propagate the tear once it is initiated. Generally, the resistance offered by a textile material when it is subjected to sudden force is generally . Resultado da A “Garota Ciborgue”, também conhecida como “Menina Cyborg” ou “Portal Zacarias Menina Cyborg”, é uma figura enigmática que surgiu na .

{plog:ftitle_list}

Resultado da Assistir Loki online: streaming, compre ou alugue. Você pode assistir "Loki" no Disney Plus em Stream legalmente. Mais recente Episódios. T2 Ep6 - Episódio 6. T2 Ep5 - .

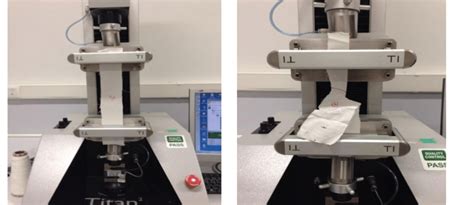

textile tearing strength test

The tear resistance test on fabrics or tear strength is measured to check how the material can withstand the effects of tearing or cuts when in . Tearing strength is the resistance of the fabric against tearing or force required to propagate the tear once it is initiated. Generally, the resistance offered by a textile material when it is subjected to sudden force is generally . 1.1 This test method covers the determination of the force required to propagate a single-rip tear starting from a cut in a fabric and using a falling-pendulum (Elmendorf-Type) .

Tear strength is a material property that determines the amount of force required to propagate a tear in a fabric. It is typically measured in pounds-force (lbf) or Newtons (N) and serves as a measure of a fabric’s resistance to . At present, the most commonly used method of fabric tearing strength test is mainly the pendulum method, tongue method and trapezoidal method. Aside from these .

plastic pellet moisture meter

The force needed to tear a fabric is known as its tear strength, an important aspect that determines a fabric’s capacity to withstand damage with time. The ASTM has developed a standard test procedure for evaluating fabric .Tensile testing tests a fabric’s strength and elongation properties, with two common methods the grab test ASTM D5034 and the strip test ASTM D5035. Tear testing measures the resistance of fabric to tearing using three popular .

Originally introduced in 1964, ASTM D2261 was most recently updated in 2013 and specifies the method for tear testing of fabrics by the tongue (single rip) procedure to measure the tearing strength of the fabric.Tear testing is a mechanical testing procedure used to measure a material’s resistance to tearing. It involves applying a controlled force to a specimen, often with a pre-initiated tear or cut, to evaluate how the material behaves under . 5.2 The force registered in a tear test is irregular, and as a consequence, empirical methods have had to be developed to obtain usable values related to tear strength. In spite of the empirical nature of the reported values, the values are considered to reflect comparative performance of similar fabrics tested and measured in the same way.

Originally introduced in 1964, ASTM D2261 was most recently updated in 2013 and specifies the method for tear testing of fabrics by the tongue (single rip) procedure to measure the tearing strength of the fabric. This test method .Originally introduced in 1964, ASTM D2261 was most recently updated in 2013 and specifies the method for tear testing of fabrics by the tongue (single rip) procedure to measure the tearing strength of the fabric. This test method .If you were to try and tear the fabric without cutting beforehand it would be very difficult and then you would be carrying out a different type of test which would almost be a tensile test. A tear starts with a snag on clothing etc., then the fabric has a small cut in it, so if the force continues the fabric will then tear. The cut before .A tear test applies a force to a material that already contains a partial fracture or rupture otherwise known as a “tear” in order to bring the material to complete failure. . (tears and holes). The more common materials that benefit from tear testing are textiles, fabrics, elastomers, rubbers, polymers, packaging and paper products. Each .

A tear in a fabric or garment generally occurs progressively along a line, and can be initiated by a moving fabric being caught on a sharp object. Several methods are used to measure tear strength, e.g. double tongue rip (tear) test, trapezoid tear test, (ASTM D5587) and single tongue tear test (ASTM D2661, BS 4303).

1.2 This test method applies to most fabrics including woven, layered blankets, napped pile, blanket, and air bag fabrics, provided the fabric does not tear in the direction crosswise to the direction of the force application during the test. The fabrics may be untreated, heavily sized, coated, resin-treated, or otherwise treated. Instructions are provided for testing . Well, the force needed to identify the tear over the fabric is measured, providing a quantitative measure of tearing strength. Of course, this method is specifically suited for lightweight and medium-weight fabrics. It is becoming popular in industries like grab, upholstery and packaging. Grab Test. The fabric test is also known as the .It is not suitable for highly anisotropic fabrics or loose fabrics where tear transfer from one direction to another direction of the fabric during the tear test is likely to occur. NOTE 1: For tests using tensile-testing machines part 2 of EN ISO 13937 describes a single tear method known as the trouser test, part 3 the wing test and part 4 .Evaluating paper with the Elmendorf Tear Test typically follows similar principles as fabric testing. However, specific adjustments might be made to the testing parameters, such as specimen size or clamping pressure, to accommodate the unique properties of paper. 13. Example of the real application of the fabric tear test:

The Wyzenbeek method uses a mechanical device to rub test fabrics against an abrading surface in a reciprocal linear motion. The abradant is typically standard #10 cotton duck canvas material or a wire screen. . Wyzenbeek results determine the number of abrasion cycles and double rubs a fabric withstands before exhibiting wear, tear strength .Textiles. Tear properties of fabrics. Determination of tear force of wing-shaped test specimens (single tear method). Experience our recommended textile testing equipment adherent to BS EN ISO 13937-3 here. BS EN ISO 13937-4:2000 : Textiles. Tear properties of fabrics. Determination of tear force of tongue-shaped test specimens (double tear test).This test allows manufacturers to determine the strength of the sample. This test complies with the following standards: ASTM D1004 Standard Test Method for Initial Tear Resistance of Plastic Film and Sheeting, and ASTM D5587 Standard Test Method for Tearing Strength of Fabrics by Trapezoid procedure.

1.2 Significance of fabric tearing strength test: Tear strength is particularly important in applications where fabrics are subjected to dynamic forces or sharp objects. For instance, in athletic wear, tear strength ensures that the fabric can withstand stretching and movement without ripping. Similarly, in outdoor textiles like tents or . They demonstrated that the properties of the fabric tearing zone, called Del zone, by analyzing of tongue tear test photographs. This Del zone arises from the stretching and slippage of longitudinal yarns (yarns parallel to the tear) along the transverse yarns as well as the stretching and alignment/jamming of these transverse yarns.

tearing strength test material

tearing strength of fabric

After carefully hand-sewing the tear in your fabric, the next step is to test the strength and durability of your repair. This will ensure that the tear will hold up well over time and prevent any further damage. . When repairing a .

In tear testing, a fabric sample is gradually subjected to increasing force until a tear starts and extends. This test gauges the fabric’s durability in high-stress conditions. Significance of Tear Test Results. Tear .The tear resistance test on fabrics or tear strength is measured to check how the material can withstand the effects of tearing or cuts when in tension. The tear strength is measured as per the ASTM D412 standard test method, which is also used to measure tensile and elongation. The standard test method measures the resistance to the formation . Tear Testing is one of the most basic tests to determine the physical strength of one fabric compared to another. Here's a simple definition: tear testing is a measurement of force required to continue a tear of a fabric specimen assuming that a tear has already been created. Two commonly used methods include Tongue Tear and Trapezoidal Tear. The fabric’s tear strength is essential when testing fabrics’ durability and mechanical qualities. In this article, you will learn about tear strength, its importance, and how to test a fabric using ASTM D2261.

Imagine the unwavering strength of Hercules applied to your favorite fabric. When you consider tensile strength, you're fundamentally looking at a material's ability to resist breaking under tension. High tensile strength is essential for ensuring that fabrics don't tear easily, especially when used in demanding applications like outdoor gear or heavy-duty upholstery.The tear resistance test, also known as tear strength, is used to determine how well a cloth can survive tearing or cutting when under stress. This pendulum-type tester has been made in accordance with industrial standards like ASTM D1424-09(2013), ASTM D624 – 00(2012), ASTM D1776, ASTM D689 and helps to measure the tearing energy.

2. Fabric Abrasion: Abrasion resistance tests simulate everyday wear and tear. You'll rub a fabric sample against a standard abrasive surface until it shows signs of wear. This test helps you determine how long the fabric will last in real-world conditions. The Elmendorf Tear Strength Tester is an instrument specially used to test the tear strength (strength) of fabrics. It uses the impact pendulum method to measure tear strength, also known as the pendulum or falling weight tear strength tester. There are manual electronic tear strength testers, digital Elmendorf tear strength testers, etc.

The tongue tear method is often used to measure the tear force and the tear strength of a fabric specimen. This method, outlined by ASTM D2261, requires a specific sample preparation where the rectangular fabric specimen is cut to form two tongues on each end which are then placed on upper and lower grips.Once tensile force is applied, the fabric specimen .Tear strength is the tensile force required to rupture a pre-slit woven fabric sample under controlled conditions. Edge tearing strength of paper is the load required to tear a sample over a V-notch fixture. Typical graph showing a tear strength test: We provide force measurement instruments and materials testing machines for tear strength testing.

10 9. How to evaluate the test results of the Elmendorf Tear Test? 11 10. How can fabric tear test results be more accurate and reliable? 12 11. What is the price range of Elmendorf Tear Testers .

plastic resin moisture meter

WEB( 4.4 / 5) (Caramuru: A Invenção do Brasil / Caramuru: The Invention of Brazil) Sinopse. A invenção de um país chamado Brasil começa em Portugal, onde o talentoso pintor Diogo Álvares (Selton Mello)cultiva a arte de embelezar a realidade, o que lhe cria alguns problemas com o comandante Vasco de Athayde (Luís Mello).

tear test of fabric|high tear strength testing